Your cart is currently empty!

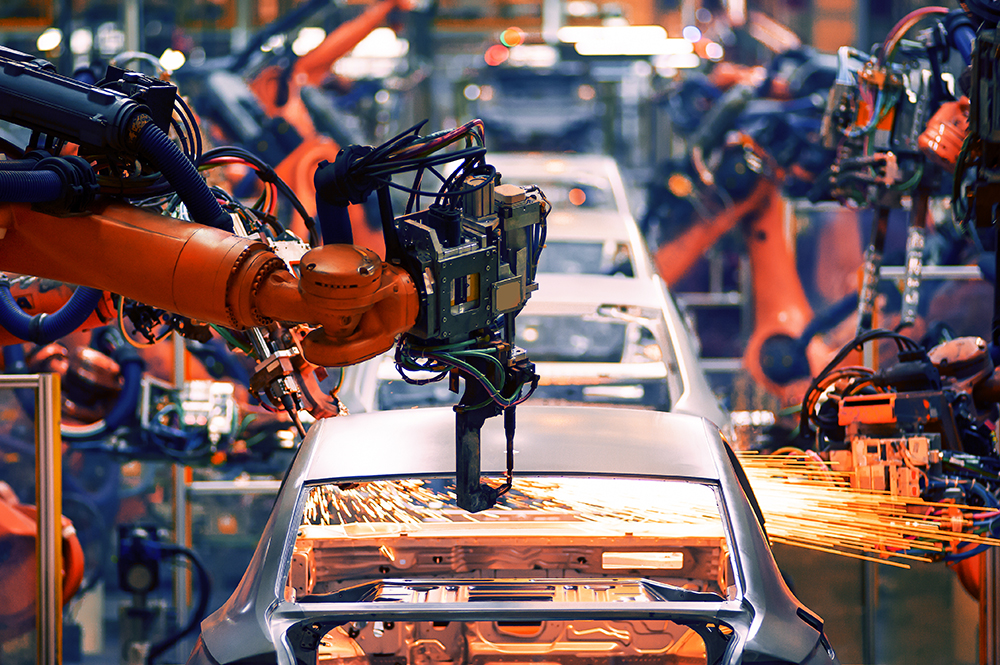

On the road again: How Goplasticpallets.com is poised to support the automotive recovery

It has been well documented that the automotive industry has faced a number of challenges over the past two years, but on the flip side the electric car market has been steadily gaining momentum. In this blog, we look at the ups and downs of the UK auto industry and explain how Goplasticpallets.com is poised to support the sector’s recovery.

UK car production fell -6.7% to only 859,575 units in 2021 according to figures from the Society of Motor Manufacturers and Traders (SMMT). The global Covid-19 pandemic has caused much of this decline, particularly with factories that produce semiconductor computer chips having to close during the period of lockdown.

The process of making a semiconductor chip ideally needs to be continuous as disruption and stoppages result in long start-up times. This inevitably has a knock-on effect for the rest of the supply chain, meaning shortages and long delays for semiconductor parts.

Although these unprecedented and unforeseeable events impacted overall car sales, Electric Vehicles (EVs) were seemingly unaffected, as UK sales reached record levels in 2021. There were 108,205 EVs registered last year, compared to just 37,850 in 2020.

This growth is expected to accelerate in the coming years as the UK prepares to ban the sale of new petrol and diesel vehicles in 2030. If we continue to look ahead in the automotive industry, there are more positives to be seen.

In January of this year, Britishvolt secured government funding to build a factory in Northumberland where it plans to mass-produce EV batteries. This further demonstrates the UK Government’s commitment to becoming a significant force in the fast-growing market of electric cars, particularly as a hub for manufacturing EV batteries.

Despite the lowest number of cars made in the UK since the 1950s, the growth in electric vehicles is encouraging. And, at Goplasticpallets.com we are well-positioned and ready to support this growth as well as the industry’s overall recovery.

How can we help automotive manufacturers?

As the UK’s leading supplier of plastic pallets, pallet boxes and small containers, we stock a wide variety of solutions ideally suited for the handling and distribution of car parts. With over 160 years of combined experience in returnable transit packaging (RTP), our experts at Goplasticpallets.com are skilled in perfectly matching customers with the products best suited to their application. Our products have been used to transport and store a range of automotive parts including seats, high-end electronics components, and gearboxes and transmission components.

Small containers for automotive applications

Our impressive range of small containers includes 12 varieties of GoEuro plastic containers which inter-stack and feature strong vertical sides to offer maximum internal volume. Our strong and durable blue RL-KLT containers are ideally suited to rigorous industrial applications, and our black RL-KLT ESD containers are moulded in premium-grade polypropylene copolymer with electrostatic discharge specification (PP ESD).

The RL-KLT ESD containers, in particular, are an ideal solution for electrical car part manufacturers because they are specifically designed to help protect sensitive devices from static discharge during handling, storage and shipping. Available in five different sizes, with the smallest measuring 300mm (L) x 200mm (W) x 147mm (H) and the largest measuring 600mm (L) x 400mm (W) x 280mm (H), the containers’ electrostatic properties control surface resistance and volume resistivity. This minimises the build-up of static and discharge that would otherwise be created by friction between the product and container.

Large containers for automotive applications

For customers who need larger containers to transport and store more bulky, hard-to-palletise items, our folding large containers (FLCs) are the go-to solution.

Our GoFLC 980 and slightly smaller GoFLC 960 are super heavy-duty containers on three runners manufactured to the automotive industry standards 1200mm (L) x 1000mm (W) and 1200mm (L) x 800mm (W) footprint, with one door on each long side, and easily replaceable side panels. Due to the special manufacturing process, these foldable plastic containers are extremely durable and robust, offering long lasting performance, even in the most demanding environments. When not in use, the containers can be folded for optimised space utilisation in return transport.

The CabCube® 1210 9F 2.0 is an extremely robust automotive sleeve pack on a footprint of 1210mm (L) x 1010mm (W). It has a unique injection moulded closed base and lid for supreme strength yet is 20kg lighter than traditional thick sided folding pallet boxes. It has a closed deck with deep recesses for quick installation and secure loading, while the base’s nine curved feet blocks reduce damage from forklift trucks and allow for safe handling and stacking of 3 units when full and 10 units when folded at a height of 222mm.

As an innovative and forward-thinking company, with core values in supplying the very best products with unbeatable service, at Goplasticpallets.com, we are poised and ready to support the automotive recovery.

Please get in touch with one of our experts to find out how we can support your business.